Table of contents

Plastic wood is the result of a modern process that uses various raw materials, such as natural fibers and recycled plastic waste, to create this material that looks like real wood, so it is excellent for those who like the effect of wood, but want to have a sustainable construction. If this is your case, read on to learn more about this subject!

Learn about the types of plastic wood most used in construction sites

In the manufacturing process of this wood, different materials can be used. Therefore, there is more than one type of plastic wood available in the market. Check out which are the three main materials:

PVC synthetic wood

This type of wood is made from a mixture of 30% virgin PVC and 70% recycled wood. Due to the union of these elements, PVC synthetic wood is very resistant and has very uniform colors that give a beautiful result to the project.

WPC Eco Wood

WPC eco-wood, on the other hand, is produced from a combination of 70% recycled wood and 30% recycled plastic. It is also strong, but its main advantage is its high durability.

See_also: Batman party: 70 ideas that will excite even the batsPlastic Wood

Plastic wood is made 100% from recycled plastics from various sources, such as industrial or even residential waste. It is resistant because it has additives that protect the material from storms and strong winds that could damage the piece. Another advantage is the fact that this product is all made from recycled plastic, i.e., it helps decrease the amount of non-recycled plastics in the world.

As you can see, there are differences between the types of wood, but all are sustainable and have their advantages. So, you just need to define what is most important in your project!

See_also: Find out what a loft is and get inspired by this living conceptWhere to use plastic wood

As consumers become more and more concerned about the environment, the demand for plastic lumber is increasing in the market. Moreover, because it is versatile, it is commonly seen in different types of projects. It is widely applied in:

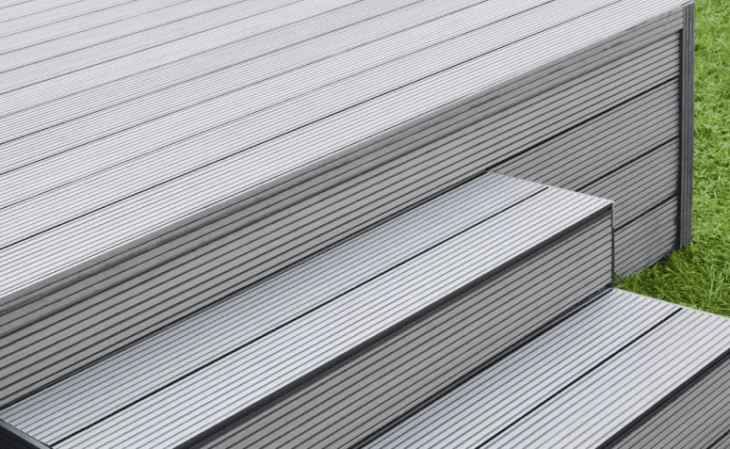

- Decks;

- Pergolas;

- Walkways;

- Playgrounds;

- Vertical gardens;

- Stairs;

- Facades;

- Garden benches.

These applications show how plastic wood can adapt to different works and can certainly beautify the sustainable project you have in mind.

Advantages and disadvantages of plastic wood

Like all types of material, plastic lumber has advantages and disadvantages. It is essential to know them to be sure that this is the ideal element for your construction. That is why we have listed below the main benefits and disadvantages of this wood!

Advantages

- Sustainability: The main advantage of plastic wood is certainly sustainability. By using it, you encourage the reuse of plastics and wood itself, in addition to reducing deforestation.

- Durability: This type of wood also has good durability, because it is resistant to humidity, to solar irradiation, it doesn't crack and doesn't present problems with fungus, termites and other pests.

- Appearance: plastic wood is used in so many projects because it is beautiful and looks very similar to natural wood, depending on the model chosen and the pigmentation of the piece.

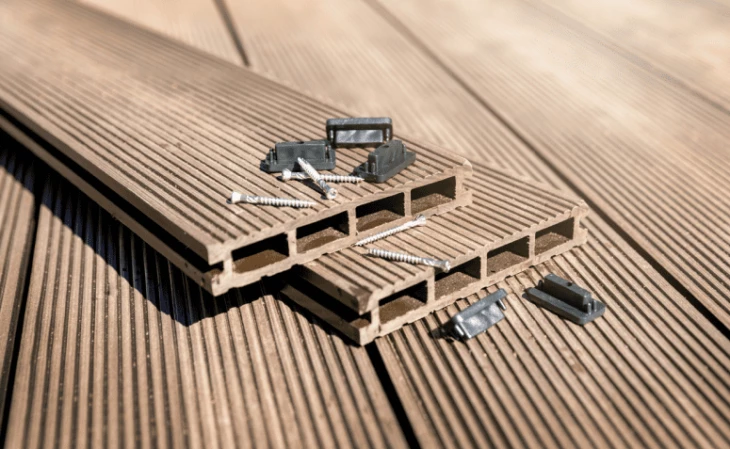

- Simple installation: This is because it is lighter, can be easily glued, nailed, or installed with clips, and has no splinters that can hurt the installer.

- It adds value to the project: Sustainable works are being increasingly sought after by consumers, and the trend is for this behavior to continue. Therefore, using plastic wood in your project can enhance its value in the future.

Disadvantages

- Cost: the biggest disadvantage of this wood is its price, which is high in many parts of Brazil when compared to natural wood, which is more expensive due to the difficulty of obtaining recycled elements for production and the technology used in the creation process.

- Unsuitable for large structures: plastic wood is not suitable for large structures, such as buildings, bridges, and roofs.

- Texture: Because it is not natural, this wood does not have the distortions and cracks that a natural piece would have. For those who want that 100% natural appearance, this fact can be a defect.

- Complex cut: The cuts of plastic lumber are preset, so it is not possible to simply cut it off during the job to adjust the material to the construction site, so if the piece needs adjusting, it will probably delay the construction progress a bit.

- It can be slippery: This wood is more slippery than natural wood, which is why it is advisable to put beads on the chosen model if it is going to be installed in a place that gets wet easily, such as around swimming pools.

Analyze well these listed points and think about what is most important for your project, so you will know if plastic wood is the most suitable for your project! If not, learn more about demolition wood in decoration.